India's Industry Sector Transition

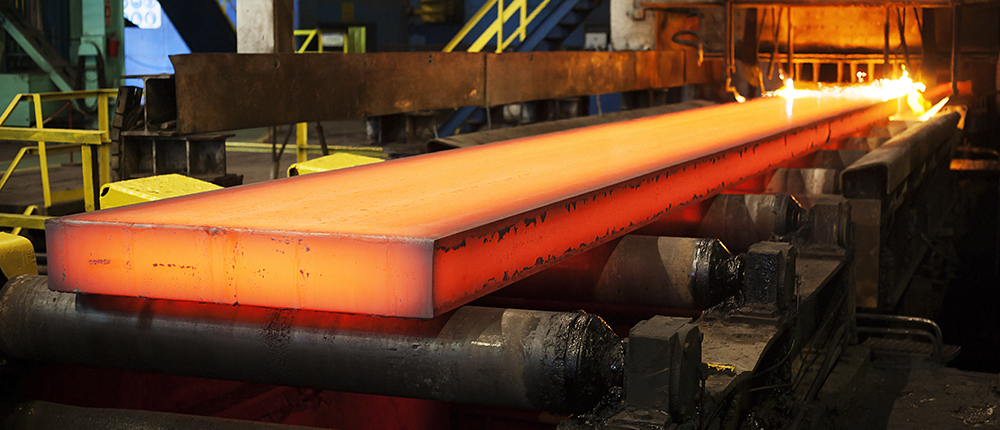

India's industrial sector has made progress towards reducing its energy consumption and emissions but more focus is needed to steer the 'harder-to-abate' sectors such as iron and steel on a sustainable path.

Indian industry contributes to a significant portion of the total greenhouse gas emissions of the country. Within the industry sector, there are sub-sectors that are highly energy intensive and have been categorised as 'harder-to-abate'.

The work under this activity focuses on deepening the understanding in:

- Steel sector

- Use of hydrogen as a cleaner fuel in sectors like transport, industry and electricity storage

Green Steel through Hydrogen Direct Reduction: A Study on the Role of Hydrogen in the Indian Iron and Steel Sector

Authors: Will Hall, Robert Millner, Johannes Rothberger, Amar Singh, Chirag K Shah

The paper outlines the potential of green hydrogen technologies, discusses its suitability in the Indian context, and provides recommendations for the next steps to advance this technology for producing steel sustainably.

Advancement in the iron and steel sectors act as propellants to the development of any nation’s economy. With their uses ranging from modern amenities in households and mechanisation of industries, they have acted as the cornerstones of progress in both the developed and developing world.

However, while steel and iron do boost the economy, it is also true that they are amongst the most carbon and resource intensive sectors. With India aiming to take a path that drives both growth and sustainability, bringing radical change to the technology required for steel production is crucial.

The policy brief titled 'Green Steel through Hydrogen Direct Reduction: A Study on the Role of Hydrogen in the Indian Iron and Steel Sector', launched at the Technology Session: Green Steel through Hydrogen Direct Reduction event on August 18, 2021 looks at how using low or zero carbon hydrogen as a reducing agent in a direct reduction (DR) plant and subsequently low or zero carbon power for the electric arc furnace (EAF) can help in green steel production. The brief suggests that:

- With proactive collaboration between companies and government, hydrogen steelmaking has the potential to drastically reduce CO2 emissions from primary steelmaking in India, making it one of the first major economies to industrialise without the need to 'carbonise'.

- To deliver an accelerated transition of the steel sector from the wide-scale use of fossil fuels to the use of low carbon energy sources, such as hydrogen, would require a holistic policy framework that provides a 'supply push' along with a 'demand pull'. This would give companies clear direction for future investments, reducing their risk of investing in low carbon production processes.

Towards a Low Carbon Steel Sector: Overview of the Changing Market, Technology, and Policy Context for Indian Steel

Authors: Will Hall, Thomas Spencer, Sachin Kumar

TERI suggests that it is possible to put the steel sector on a pathway to reduce emissions to near zero levels soon after 2050, making India the first country to industrialise while decarbonising its steel production.

The initial analysis of the steel sector was published as a consultation document titled 'Towards a Low Carbon Steel Sector: Overview of the Changing Market, Technology, and Policy Context for Indian Steel'. According to the paper -

- In the short to medium term, both energy efficiency and resource efficiency will play a key role in improving the steel sector's performance in the energy and environmental domain.

- To fully decarbonise the steel sector in the long-term, futuristic technologies (primarily hydrogen-based) will have to be adopted by the Indian steel industry.

- This would require proactively pushing for international collaborative research, development and demonstration (RD&D) programmes and engaging in international consortia for cleaner technologies in the sector.

The consultation document was released by Sh. Dharmendra Pradhan, Honourable Union Minister of Steel, at the 2020 edition of the World Sustainable Development Summit, TERI's annual flagship summit.

The Potential Role of Hydrogen in India: 'Harnessing the Hype'

Authors: Will Hall, Thomas Spencer, G Renjith, Shruti Dayal

By 2030, costs of "green hydrogen" from renewable energy will fall more than 50% and will start to compete with hydrogen from fossil fuels, the report says.

Hydrogen has long been the 'fuel of the future' but has to-date never quite made it as a major player in the energy system. Today, a number of key developments suggest that the time for a substantial role for hydrogen in the energy system has come. First, concern about global climate change is increasing, and it is becoming clear that decarbonisation of the energy system necessitates new low carbon fuels and chemical feedstocks.

Second, technology innovation in electrolysers and electricity generation from zero-carbon renewables is making the prospect of abundant low carbon hydrogen realistic.

This report provides a comprehensive assessment of the scope for deploying hydrogen in the Indian energy system, with the goals of achieving sustainable, secure and affordable energy for all. It gives a techno-economic assessment of the full range of potential production routes. It examines the potential for hydrogen to be competitive with existing fuels in major energy consuming sectors like industry and transport. It also studies the role of hydrogen as a storage option in the power system, helping to provide long-term storage for renewable energy. Finally, the report gives an overview of the cross-cutting issues related to hydrogen deployment, including a detailed modelling exercise of the potential to supply hydrogen based on variable renewables to India's industrial clusters.

The report comes up with nine key conclusions:

- A virtuous circle for hydrogen technology is emerging

- Demand can grow five-fold by 2050, but supportive policy is still required to derive the full benefits of hydrogen

- By 2030, costs of “green hydrogen” from renewables will fall more than 50% and will start to compete with hydrogen from fossil fuels

- Hydrogen is not always the most efficient option, and its use should be reserved for cases where no alternatives exist

- In industry, hydrogen can start to compete with fossil fuels in certain applications already by 2030

- In transport, even in heavy duty segments, BEV vehicles will become very competitive, reducing the use of H2 to very long-distance transport

- In power, H2 could provide an important source of seasonal storage, but is expensive and only required in high RE systems

- Green hydrogen production could require around 1000 TWh of green electricity by 2050, placing further pressure on power system decarbonisation

- Constant H2 supply to industry is possible and cost-effective with VRE, but open access RE, curtailment and H2 storage characterise the optimal system

With the potential to grow five-fold by 2050, coupled by the projection that costs associated with 'green hydrogen' from renewables will fall by more than 50% by 2030 to start competing with hydrogen from fossil fuels makes hydrogen immensely lucrative for climate action.

Circular economy for plastics in India: A roadmap

Report Authors: Shilpi Kapur Bakshi, Mehar Kaur, Shweta Gautam

The plastic circularity roadmap aims to decouple plastic production from virgin fossil fuel, and incentivise its reduce, reuse, and recycling, thus bringing down plastic waste as well

The plastic value chain spans from the extraction of raw material for plastic production over several steps, all the way to the end-of-life management and disposal of plastic waste. The value chain is extremely carbon intensive both on the demand and supply side. In addition, the existing waste management practices in India are unable to support the urban waste generated from plastic, which is becoming a major issue. This poses a significant challenge as the world aims to limit global warming below 2°C. In hopes of achieving emission reduction targets, the industry sector has been focusing on reducing the sectoral greenhouse gas (GHG) emissions from production (supply-side) of widely used resources such as steel, cement, and plastics. However, achieving the targets required to keep global warming below 2°C is possible only when reduction in supply-side emissions is complemented with demand-side management.

The report 'Circular Economy for Plastics in India: A Roadmap', prepared by TERI with support from the Children's Investment Fund Foundation (CIFF), was released at the WSDS 2021 Business Track- Collaborative platforms to fast-track India Inc.'s 'race to zero' emissions. The report identifies opportunities across the entire value chain of plastics with specific focus on the downstream issues of avoiding waste and fostering reuse and recycling. Drawing upon the learning from existing best practices across the world, the roadmap details the potential impact of the measures which include use of recycled plastics and waste as a substitute for virgin polymers, eco-design to reduce absolute material consumption and ease of disassembly of final product from demand and supply sides, under three circularity scenarios for India: Business as Usual (BAU), Moderate, and High ambition Resource Efficiency (RE) and Circular Economy (CE).

The report has three key objectives supported by measurable action plans that look into:

- Adopting sustainable material solutions – use of bio-based polymers, substitution of virgin polymer with recycled polymer, and dematerialisation of plastic products.

- Increasing supply of good quality secondary plastics feedstock (recycled plastics); and

- Invent, innovate, and encourage alternative uses of problematic plastic waste.