Guar gum powder is extracted from the guar seeds after a multistage industrial process. The production technique depends upon the desired product.

Guar gum is a green natural biopolymer, water-soluble polysaccharide derived from the seeds of the guar plant (Cyamopsis tetragonoloba), a legume primarily cultivated in India and Pakistan. The seed is composed of the hull (14–17%), the endosperm (35–42%), and the germ (43–47%). The germ and hull of the guar seeds are called a ‘Guar meal’, which is rich in protein. The commercially important part of the guar seed is the endosperm.

Production of Guar Gum

Guar gum powder (Figure 1) is extracted from the guar seeds after a multistage industrial process. The production technique depends upon the desired product. This versatile substance is composed mainly of sugars–galactose and mannose. Usually, the mannose:galactose ratio is about 2:1, and it is a linear chain of -D-mannopyranosyl units linked (1→4) with single-member, -D-galactopyranosyl units occurring aside branches. It is widely recognized for its remarkable ability to thicken, stabilize, and form gels, making it indispensable across various applications in the oil and gas industry. Guar gum appears as a white to off-white powder and is known for its high solubility in both cold and hot water. When mixed with water, it forms a viscous gel or thick liquid, depending on the concentration, thereby making it a powerful thickening agent. Guar gum’s water-binding capacity is significantly higher than many other gelling agents, such as Xanthan gum, Polyanionic Cellulose (PAC), Carboxymethyl Cellulose (CMC), Polyacrylamide, Carrageenan gum, and Locust gum, allowing it to enhance the texture and consistency of many products with a minimal amount used.

Figure 1: Guar gum powder is extracted from the guar seeds after a multistage industrial process

Figure 1: Guar gum powder is extracted from the guar seeds after a multistage industrial process

Modified Guar Gum

Modified guar gum refers to guar gum that has undergone physical, chemical, or enzymatic modifications to alter its molecular structure, enhancing its properties and expanding its range of applications. The guar gum splits are converted into Fast-Hydrating Guar Gum (FHG), which is then modified into Carboxymethyl Hydroxypropyl Guar Gum (CMHPG), cross-linked with nanoparticles to enhance the thermal stability of the solution. The modified guar gum polymer (CMHPG) has an improved hydration rate of up to 90–95%, imparting viscosity within 10–15 minutes and forming a nearly water-clear, transparent paste. The modified CMHPG biopolymer is a gelling agent/viscosifier and it is thermally stable with the temperature ranges of 120°C–180°C. Modified CMHPG has excellent compatibility with many electrolytes even with a minor amount of water-soluble organic compounds or solvents. It can tolerate up to 50% methanol/alcohols without appreciable loss in viscosity. Being partially anionic, it is compatible to cationic, anionic or non-anionic additives and can improve overall electrolyte tolerance. CMHPG is known to offer excellent rheological properties, solubility, and stability, along with resistance to microbial attack and compatibility with various chemicals and auxiliaries. Therefore, it has a wide range of applications in oil and gas production within the petroleum industry. Such modifications improve the gum’s performance in specific environments and industries, making it more adaptable to diverse needs.

Benefits of Modified Guar Gum

1. Enhanced Functionality: The modifications enhance guar gum’s properties like solubility, viscosity, stability, and water retention, making it more efficient for specific oil and gas industrial uses.

2. Cost-effectiveness: Modified guar gum is often considered more economical than other synthetic alternatives in various applications, offering a natural and biodegradable solution.

3. Environment-friendly: Derived from a renewable plant source, modified guar gum is a sustainable alternative to synthetic chemicals, thereby aligning with growing demands for eco-friendly products.

4. Versatility: The various types of modifications allow guar gum to be tailored to specific industrial needs, from food processing to high-performance applications in oil extraction.

Applications of Green Biopolymer in Oil and Gas Industry

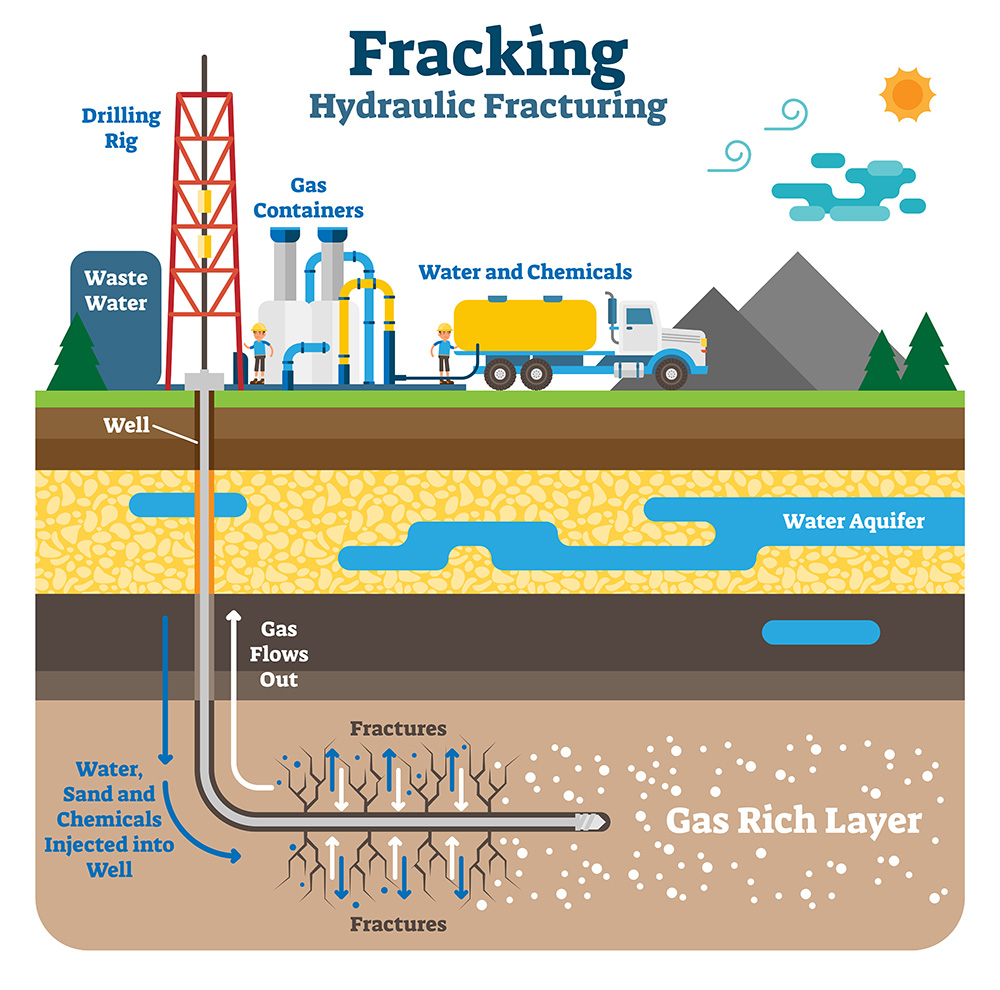

CMHPG is a high-viscosity gel used in hydraulic fracturing (Figure 2), providing optimal fracture conductivity and preventing premature settling. It hydrates efficiently in fluids containing high concentrations of monovalent and divalent ions, making it ideal for operations involving sodium chloride brines or recycled water. CMHPG’s cleaner break profile helps preserve fracture conductivity and maximize well productivity. It is compatible with standard breakers and exhibits excellent thixotropic behaviour, allowing it to regain viscosity after high shear. Hydraulic rock fracturing is crucial for unlocking hydrocarbon resources from low-permeability formations like shale. Conventional guar gum faces limitations in high-temperature environments and challenging water-holding capacity. CMHPG is a purpose-engineered polymer solution designed to overcome these limitations, such as high temperature-pressure conditions, and deliver superior performance in demanding fracturing applications. CMHPG-based gels maintain functional viscosity and proppant suspension capabilities, outperforming both guar gum and Hydroxypropyl Guar (HPG).

Figure 2: Hydraulic fracturing application process

Figure 2: Hydraulic fracturing application process

Conclusion

CMHPG is a revolutionary polymer for hydraulic fracturing, combining carboxymethyl and hydroxypropyl modifications on the guar backbone. It offers exceptional thermal stability, robust performance in brines, reduced formation damage, and versatile cross-linking behaviour, making it ideal for mid-to-high temperature operations. Its engineered advantages balance high performance with practical environmental considerations, making it a vital component in hydraulic fracturing. As the energy sector evolves towards more efficient and sustainable practices, CMHPG can be a critical enabler of advanced, environmentally responsible fracturing solutions.