In a world grappling with the persistent threat of environmental devastation, particularly from the silent creep of oil pollution, a hero emerged from seven years of dedicated research at The Energy and Resources Institute (TERI) in India. This was not a hero of myth, but a cocktail of microbes: Oilzapper, an eco-friendly solution designed to combat the catastrophic fallout from accidental oil spills and the insidious hazard of oily sludge. Partially supported by the Department of Biotechnology (DBT), this indigenous technology quickly became a globally recognized microbial consortium for bioremediation of oil spill sites, mainly on land.

For too long, the traditional method of managing oily sludge or oil contaminated land – a hazardous hydrocarbon waste generated by oil refineries – involved dumping it into specifically constructed pits. But these pits were not just an eyesore; they presented a multitude of problems: a limited availability of land in oil refineries, the potential for dangerous seepage into the earth and groundwater, and exorbitant construction costs. A single polymer-lined pit, for instance, could cost approximately 10 million Indian rupees and would fill up in a mere three to four years. The world desperately called for an alternative, a more sustainable answer.

Oilzapper rose to the challenge, not with brute force, but with the subtle power of nature. It was meticulously crafted as a "cocktail" of five distinct bacterial strains, carefully derived from natural environmental sources. These microscopic warriors were then immobilized and blended with a carrier material: powdered corncob, making them ready for deployment.

The secret to Oilzapper's prowess lay in its fundamental mechanism: these bacterial strains "feed on hydrocarbon compounds" found in crude oil and oily sludge. Through their natural metabolic processes, they transform these harmful substances into water and fatty acids. This bio-friendly approach to detoxifying hydrocarbon pollutants and cleaning up oil slicks was nothing short of revolutionary.

The contrast with the old ways was striking. To clean up 20,000 tonnes of oily waste, where once several costly pits were needed, only 100 tonnes of environment-friendly Oilzapper were now required. Beyond efficiency, Oilzapper brought critical safety and environmental benefits. When oil spills occurred at sea, the lighter oil would float, swiftly catching fire and endangering entire ecosystems. On land, pipeline leakages or pilferage could also lead to fire hazards and pollute precious groundwater and air. Oilzapper provided a swift counter-measure, capable of remediating a 20% oil contamination level (e.g., 200 grams per kilogram of oil) in approximately three to five months.

But Oilzapper's impact stretched far beyond mere cleanup; it became a beacon of hope for restoring livelihoods and ecology. In India,cropland, once contaminated with crude oil spills, have been successfully reclaimed, allowing farmers to return to their fields and restore their source of income. Similarly, individuals whose livelihoods hinged on fisheries, often devastated by oil slicks in rivers and lakes, found renewed hope as Oilzapper was used to cleanse these vital water bodies. It truly stood as an "outstanding example of science being used for the benefit of humankind".

Restoration of oil spill site in farmers land, ONGC Mehsana Asset (Ex- situ Bioremediation)

Before Bioremediation of oil spill in farmers land

After Bioremediation of oil spill in farmers land

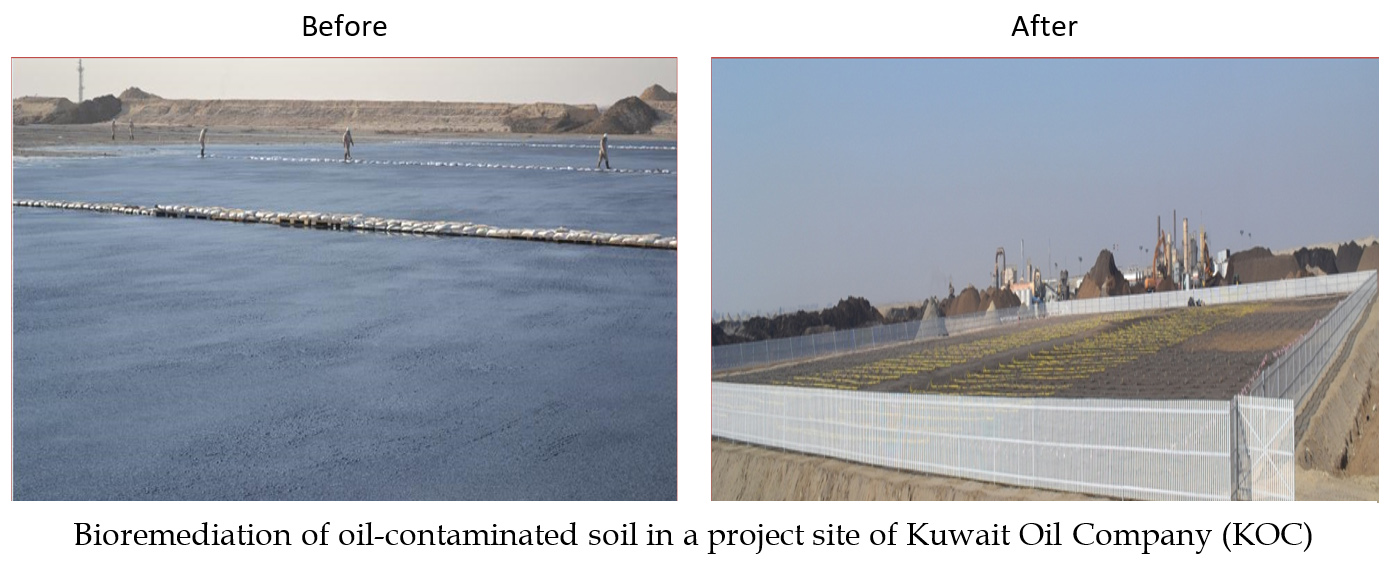

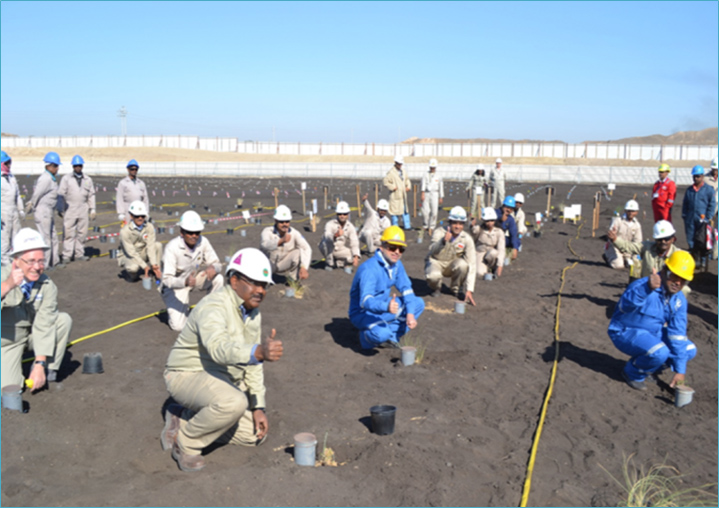

The scale of Oilzapper's triumph is immense. It has been extensively used for the clean-up of oil spill sites, treatment of oily sludge, and oil-based drill cuttings. Major oil companies across India and internationally embraced the technology, including ONGC, IOCL, BPCL, OIL India Limited, Reliance Industries, Kuwait Oil Company (KOC), and Abu Dhabi National Oil Company (ADNOC).

One of its most notable achievements includes a project for Kuwait Oil Company (KOC) in Kuwait, where TERI successfully treated 217,000 m³ of oil contaminated soil.

Restoration of oil lake in KOC oil field after Bioremediation

Field trial of bioremediation of total petroleum hydrocarbon contaminated land at Nkeleoken, Eleme LGA, Nigeria oil field by using Oilzapper technology

Application of Oilzapper at Bioremediation site at Nkeleoken, Eleme LGA, Nigeria

Visit of officials from Hydrocarbon Pollution Remediation Project (HYPREP), and Porta Har Court University, Nigeria at Bioremediation site at Nkeleoken, Eleme LGA, Nigeria

In India, TERI undertook significant bioremediation projects for Oil India Limited (OIL) in Assam and Arunachal Pradesh, successfully completing in-situ bioremediation of 20,671 m³ of oily sludge and contaminated soil, with the oil concentration (TPH) reduced to less than 5,000 mg/kg in 4–6 months. More recently, TERI commenced treating approximately 2000 metric tonnes of waste oily sludge at Chennai Petroleum Corporation Ltd (CPCL), aiming to reduce TPH to below 0.5%.

As of March 2025, over 1.3 million tonnes of contaminated soil have been treated by Oilzapper globally.

To ensure this remarkable innovation could reach every corner of the world where it was needed, ONGC TERI Biotech Ltd (OTBL) was established on March 26, 2007, as a joint venture between TERI and ONGC. OTBL is providing bioremediation services using Oilzpaper at a commercial scale. For details visit www.otbl.co.in.

The large-scale production of Oilzapper takes place at TERI's cutting-edge Fermentation Technology Research Centre (FTRC) at TERI Gram, Gurugram. This facility boasts an impressive array of bioreactors with capacities ranging from 1 liter up to 15,000 liters, ensuring the ability to meet substantial demands. For safe transport, the product is neatly packed into sterile polythene bags and sealed aseptically, with a shelf life of three months at ambient temperature.

Fermentation Technology Research Centre at TERI Gram for mass scale production of Oilzapper

Oilzapper, a testament to relentless research and environmental dedication, continues its vital work, turning the tide against oil pollution and writing a new chapter in the story of sustainable industrial biotechnology.

FOR FURTHER DETAILS PLEASE CONTACT

Dr Banwari Lal, Senior Fellow,

Bioremediation Technology, Environmental & Industrial Biotechnology,

Email: banwaril@teri.res.in The Energy and Resources Institute (TERI), Darbari Seth Block India Habitat Centre Complex,

Lodhi Road, New Delhi – 110003

Tel: +91-11-2468 2100 or +91-11-2468 2111 Fax: +91-11-2468 2144 or +91-11-2468 2145