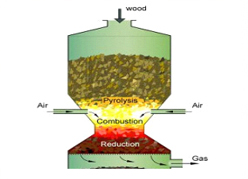

Biomass gasification is a process of converting solid biomass fuel into a gaseous combustible gas (called producer gas) through a sequence of thermo-chemical reactions. The gas is a low-heating value fuel, with a calorific value between 1000- 1200 kcal/Nm3 (kilo calorie per normal cubic metre). Almost 2.5-3.0 Nm3 of gas can be obtained through gasification of about 1 kg of air-dried biomass. Since the 1980's the research in biomass gasification has significantly increased in developing countries, as they aim to achieve energy security.

TERI independently began research work in gasifier technology in the mid-1980s. Since, the gasifier technology has been customized for a range of direct-heat application and tested successfully in the field. Silk processing, large-cardamom drying and gasifier-based crematoria are a few examples of the applications worked on at TERI. This technology is slowly replacing both traditional biomass use and gas-powered systems, as it provides an excellent de-centralized source of energy at an affordable cost. Apart from rural households, biomass fuels are the main source of energy to a large number of small, rural and cottage industries.

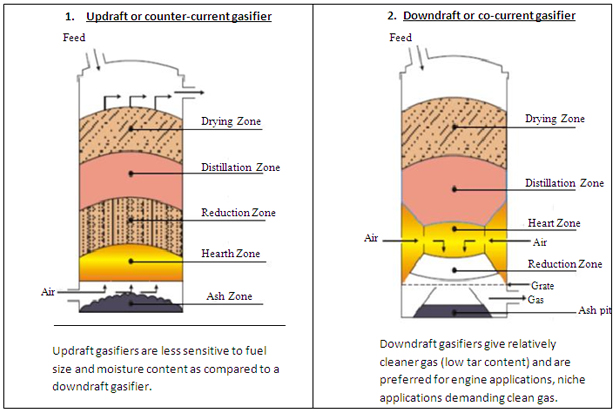

There are 2 main types of biomass gasifiers

Salient Features of TERI's biomass gasifier

- Throat-less patented design

- Multi-fuel capability

- Low initial investment

- Better conversion (solid gas) efficiency (>75%)

- Production of clean gases in the exhaust

- Available in both, downdraft and updraft mode

- Can be customized for a variety of applications

- Thermal application to meet the process heat requirement

- Power application for rural electrification and captive use

- Shaft powder

- Reduced deforestation through fuel wood savings

- Substantial reduction in diesel/kerosene/furnace oil cost (since 3-4 kg of biomass can replace 1 litre of petroleum fuel)

- Use of castable insulation material in the fire box capable of withstanding high temperatures (upto 1860°C)

- Since biomass is a carbon neutral fuel, the net emission of CO2 would amount to zero

The then-applied technologies in brick manufacture such as clamps, downdraught kilns, and BTKs require huge proportions of highly polluting coal (with an ash content as high as 40%), firewood, and biomass as fuel. In fact, the coal consumed by this industry was an astronomical 24 million tonnes.