Resource Efficient Technologies in SRC has been working on making plastic environment-friendly

The resource efficient technologies (RET) group in SRC focuses mainly on the development of environment-friendly plastics with a special emphasis on biomaterials, using naturally available renewable resources. The group works on the following thrust areas to be able to come up with ways to meet the challenge of consumption and disposal of the seemingly indestructible material.

Biodegradable Plastics

Two kinds of biodegradable plastics have been developed – synthetic polymer blends with natural biopolymer such as starch and cellulose etc. and fully biodegradable plastic (no synthetic polymer). Biodegradability of these bio-based composites was enhanced by increasing the content of biopolymers. The mechanical properties of these bio-based composites were almost at a par with neat synthetic polymers.

Salient Features

|

Synthetic and bio-polymeric composites |

Completely bio-based nanocomposites |

|

|

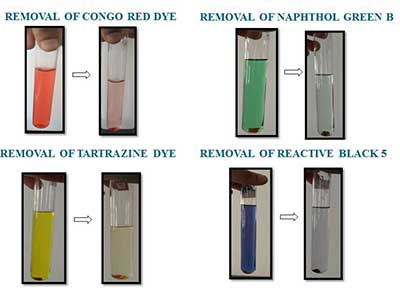

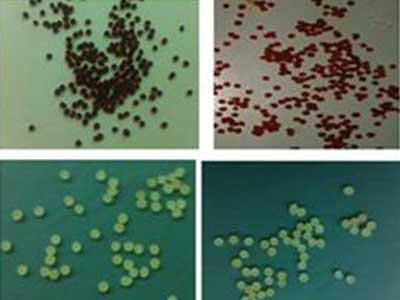

Superabsorbent materials

Superabsorbent nanomaterials are developed using bio-based polymers. They can absorb and retain extremely large amounts of a liquid relative to their own mass. They can be sustainable alternatives to petrochemical-based superabsorbent materials and find application in removal of toxic dyes and heavy metals from industrial waste water, in controlled release of insecticides and herbicides and in medical applications such as controlled drug release and wound dressing.

Fire retardant nanocomposites

Fire retardant nanocomposites have been developed using recycled commingled plastic waste with non-halogenated fire-retardant additives (as commonly used FR additives are halogenated and can release toxins) and nanofillers as reinforcement. These nanocomposites are environment-friendly plastics and can find application in various fields such as making of panels, furniture and other possible building materials apart from packaging for storage and transport of non-food products.

Salient features

- Mixture of comingled plastic waste consisting of Polyethylene, Polypropylene etc. can generate value-added products that can be used in the manufacture of toys, furniture, panels, enclosures etc.

- Have the twin advantages of improved strength and being fire-retardant

- Can be easily implemented by industries manufacturing recycled products without altering their existing infrastructure

Biomedical nanocomposites

The group has developed biocompatible nanocomposites using nanohydroxyapatite that can be used as bone implants. Mechanical properties of these nanocomposites are similar to that of the human bone.

Salient features

- Biocompatible

- Mechanical properties can be tailored as per requirements

- Immersion in Synthetic Body Fluid showed appetite formation similar to bone

- Some of these are completely bio-based

- Preliminary studies don't show cytotoxicity

Polymer processing and testing laboratory

The group is also equipped with sophisticated and versatile testing equipment for polymer processing and testing services as per standard test procedures. The main objective of their laboratory is to provide cost-effective analytical services, research and development studies for industries, research and development activity for academic institutes and other in-house research activities.

Glossary

Synthetic polymer - Plastics made from petrochemical resources

Biopolymer - Polymers derived from renewable sources

Nanocomposites - Polymer composites consisting of nano-sized particles

Halogenated fire retardant additives - Additives that release toxic sulphur by-products during combustion

Synthetic Body Fluid - Solution with ion concentration similar to that of human bodily fluids

Cytotoxicity - Toxicity to living cells